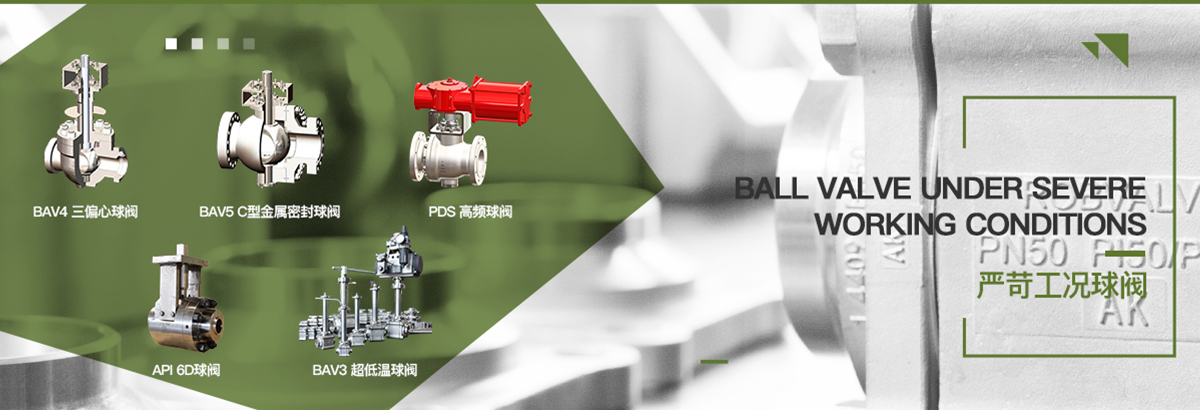

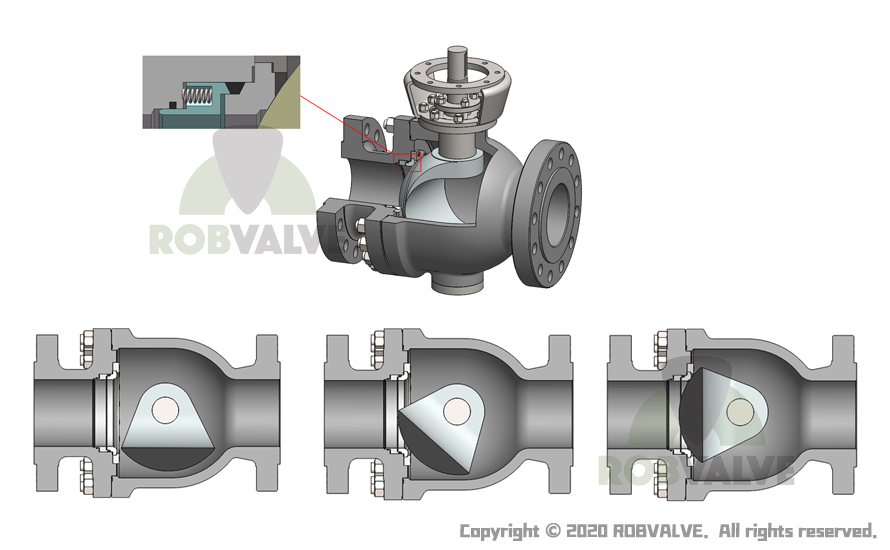

BAV5 C Ball Metal Seat Valve

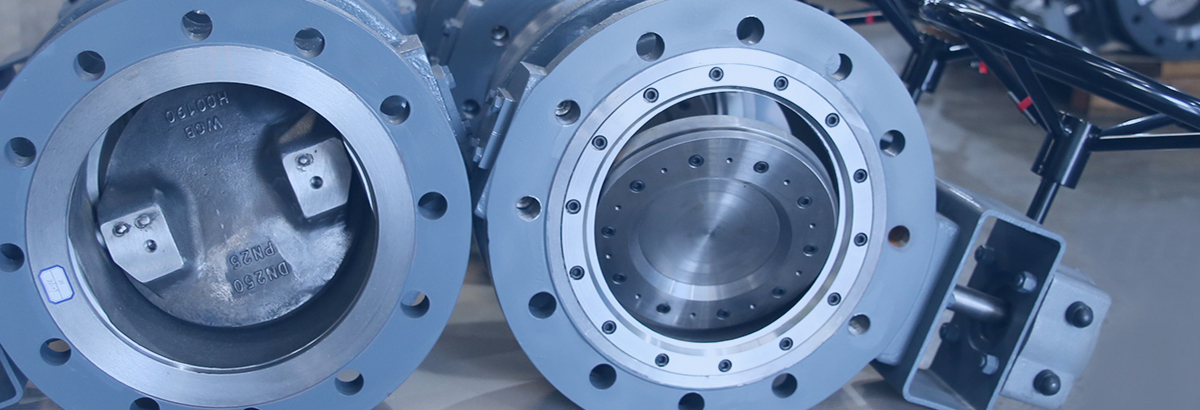

| Size range: | 2"-48"(DN50 - DN1200) |

| Pressure Rating: | CLASS150 - CLASS900 (PN16 - PN150) |

| Temperature Range: | -196℃~ +650℃ (-320℉ ~ +1202℉) |

| Body Construction: | Side Entry, 2-piece or 3-piece |

| Material forming process: | cast, forged |

| Operation type: | manual, worm gear, pneumatic, electric ,etc |

Standards and Specifications

| Design and manufacture standard: | API 6D, API 608, MSS SP-72 |

| Temperature and pressure rating: | ASME B16.34, EN 12516-1 |

| Mounting flange: | BS EN ISO 5211 |

| Connection flange: | ASME B16.5, ASME B16.47, ASME B16.11, ASME B1.20.1, ISO 7005, EN 1092-1 |

| Face to face: | ASME B16.10, ISO 5752, EN 588, EN 12982 |

| Inspection and testing standard: | API 598, API 6D, EN 12266-1, EN 12284 |

| Low emission conform to: | ISO 15848-1, TA-Luft, EPA Method 21 |

Material

| low temperature CS: | WCB, LCB, LCC, A105, etc |

| Austenitic stainless steel: | CF8M, CF8, CF3M, CF3, F316, F304, etc |

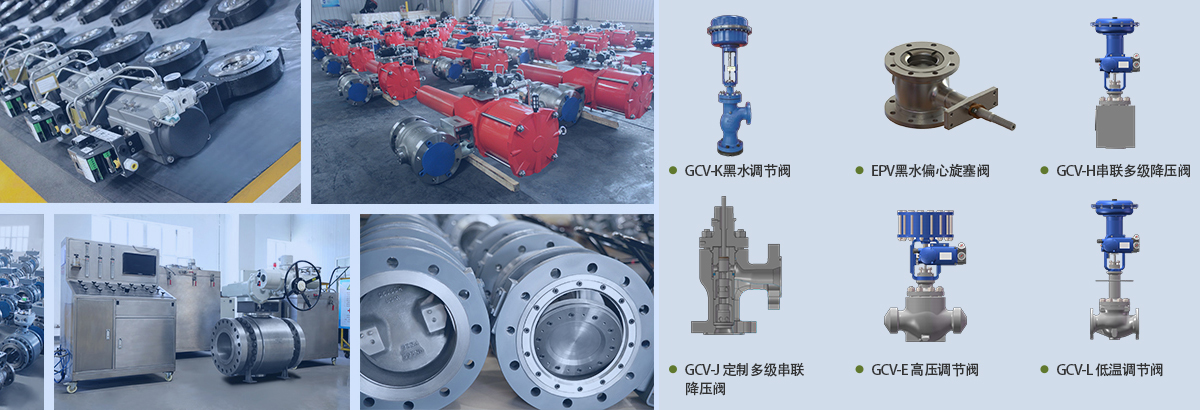

Industrial applications

Coal chemical industry, coal-to-oil, coal-to-olefin, etc. Polysilicon industry. Oil refining and catalytic cracking unit. Polyurethane industry

Product features

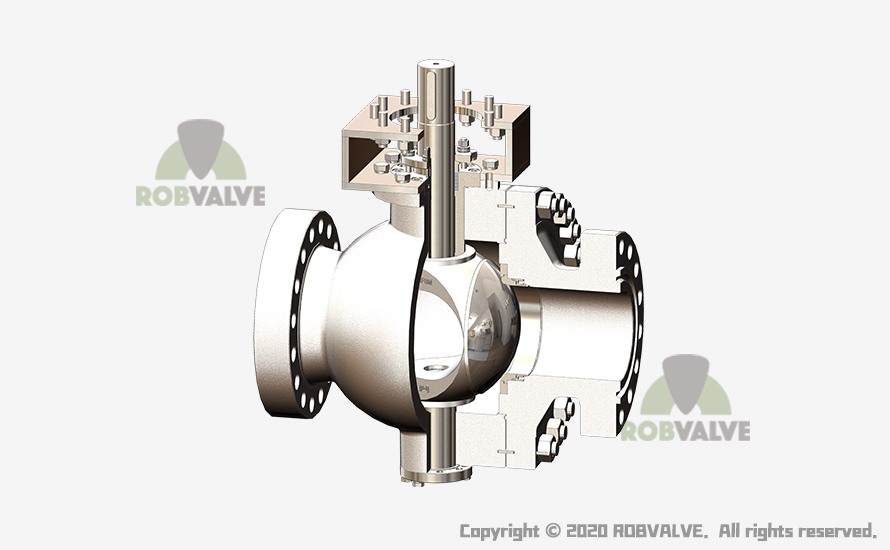

- Single seat, full bore design, reliable sealing performance, convenient operation, high flow capacity and low flow resistance.

- Quarter turn Trim, low operating torque, trip seal surface apart from full closure, no friction, no wear, extended service life.

- With sealing surface self-cleaning function, when the valve core is closed, it can automatically clean the particles and impurities bonded to the sealing surface.

- Hemisphere structure, eccentric design, compared with the whole ball has a better cleaning function, not easy to accumulate slag, suitable for all kinds of harsh conditions.

- Valve seat and valve core with eccentric - wedge tight seal and spring pre - tight seat seal, torque seal design

- There is no media retention area inside the valve body and it will not adhere to the valve body cavity.

- Its design has "fire safety" high temperature resistance characteristics, anti - static structure.